- Description

- Config

- Technical

- Samples

- Video

- Download

Introduction:

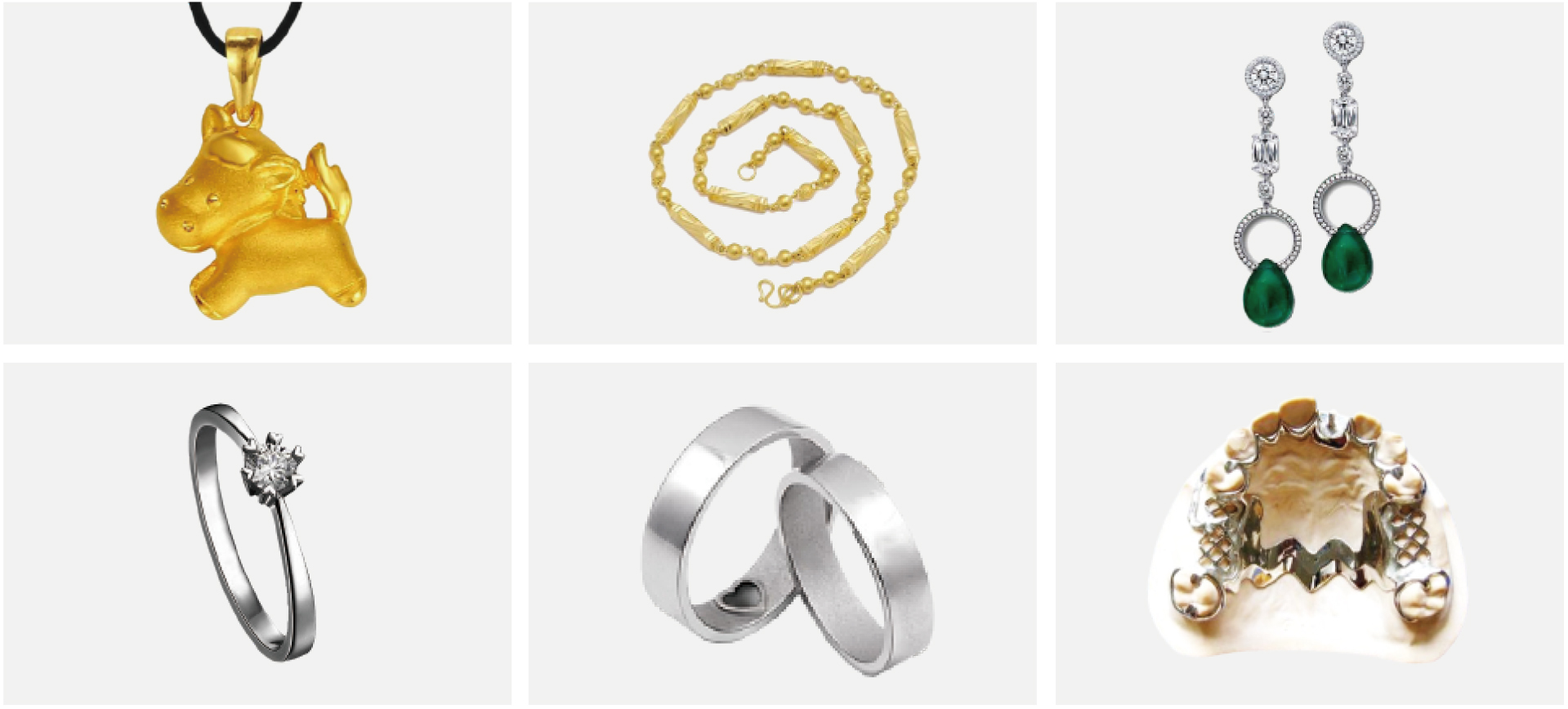

The jewelry spot welding machine is specially designed for the electronics industry and the jewelry industry. The system is stable and easy to operate. It can be used for gold and silver jewelry electronic components to fill holes, spot welding sand holes, welding inserts and so on.

Feature:

■ High single-pulse energy.low power consumption, low heat effect, and it is not hot when soldering.

■ High effieciency YAG crystal to ensure the best beam quality and energy.

■ No need to fill the solder,high welding speed ,reliable joint, small workpiece deformation,good molding.

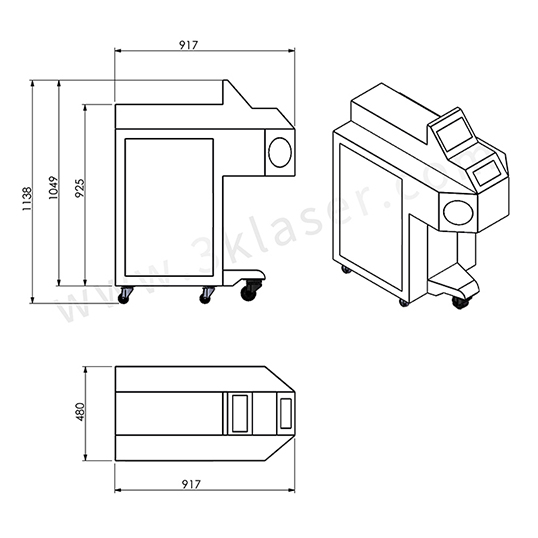

■ The water-cooled integrated laser welding system is compact and small in size.

■ Stable laser power supply to ensure the system able to operate in 24hours.

Application:

It is widely used in the precision welding of jewellery, dentures, sand watches, hairsprings, integrated circuit leads, various tiny, heat-sensitive parts, suitable for optoelectronic devices, electronics, communications, machinery, automotive, military, gold jewelry and other industries.

Materials:

Applicable to gold, silver, aluminum, copper, stainless steel, carbon steel, chromium, nickel, titanium, tantalum and other metals or alloys.

| Jewelry Spot Welding Machine | Items | Spec | Mark |

| Laser Rod | YAG | ||

| Xenon lamp | Pulse | ||

| Laser Power | Strengthen Pulse Power Supply | ||

| Cooling System | Cooling Tank | Laser dedicated | |

| Control System | Single chip microcomputer | ||

| Surveillance System | Microscope system |

| Performance/Model | Unit | SK-LSW100 | SK-LSW150 | SK-LSW200 |

| Max Output Power | W | 100 | 150 | 200 |

| Wavelength | nm | 1064 | 1064 | 1064 |

| Laser Generator | Nd:YAG | Nd:YAG | Nd:YAG | |

| Pump Source | Xenon lamp | Xenon lamp | Xenon lamp | |

| Max Pulse Energy | J | 60 | ||

| Pulse Width | ms | 0.1-20 | ||

| Max Pulse Energy | Hz | 0.5-50 | ||

| Spot Diameter | mm | 0.1-2 | ||

| Welding Depth | mm | ≤2.5 | ||

| Cooling System | Water cooling | Water cooling | Water cooling | |

| Voltage | 220V±10%,50Hz | |||