- Description

- Config

- Technical

- Samples

- Video

- Download

Features

1.The energy, pulse width, frequency and light spot size can be adjusted in a large range to realize different welding effects.

2.Use advanced light shielding system to eliminate the irritation to eyes by light during working.

3.Human-based design accords with ergonomics, avoiding fatigue after long time working.

Advantages

1. High-performance laser power supply, single pulse of high power, low power consumption and not hot when welding.

1. It doesn't need to fill the solder, welding fast,spot distributed evenly,the workpieces deformation is small, beautiful appearance.

3. Ceramic laser cavity imported from internationally famous manufacturers to ensure the machine is high quality and high performance.

4. Unique YAG crystal cooling method to improve the beam quality and xenon lamp lifetime, reducing the use of cost.

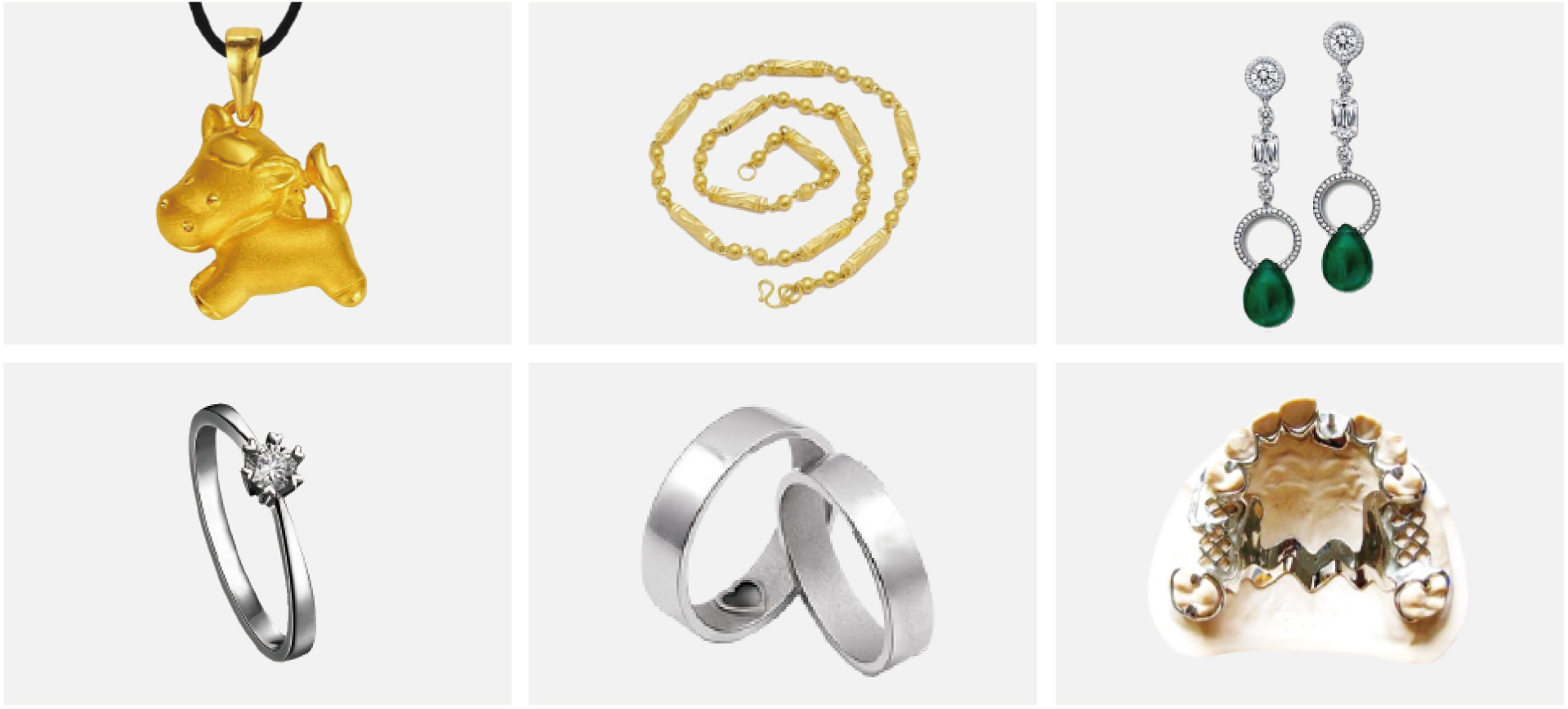

Application

Jewelry laser welder widely used in aviation, aerospace, sports products, jewelry, golf head, medical instrument, titanium alloy denture, instrument, electronics, machinery, automobile, etc, especially for the perforating of gold and silver jewelry, spot welding, repairing, inlay and welding of claw.