- Description

- Config

- Technical

- Samples

- Video

- Download

Introduction:

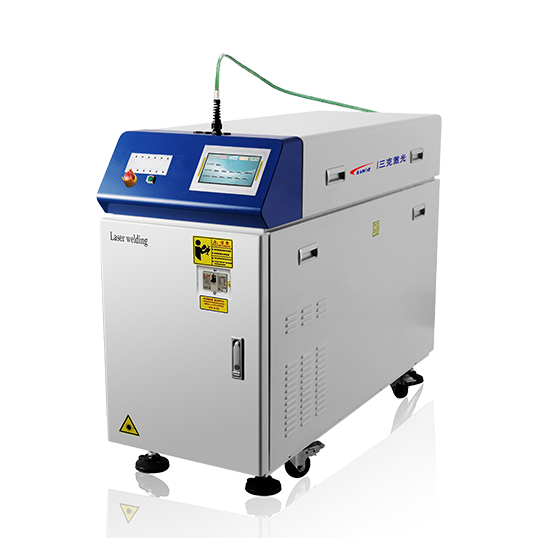

The fiber-optic transmission laser welding machine has an "energy feedback technology" to maintain the stable processing state of the machine and create high-quality precision welding. This series of welding is composed of welding mainframe and a variety of different welding workbench. It realizes time-sharing, energy-dividing and multi-station simultaneous welding through flexible internal optical combination, which can economically realize the needs of different customers.

Feature:

■ “Energy Feedback Technology” ,real-time processing of feedback control performance and waveform

control functions to ensure stable laser output power and reduce product defect rate.

■ The laser beam becomes more uniform and stable after pass through the fiber which improve the

welding quality.

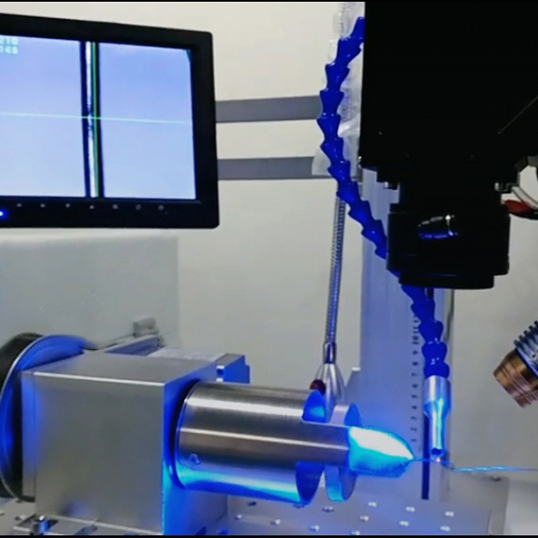

■ Optional combination of ordinary welding head, hand-held welding head and galvanometer system,

spot welding and seam welding in the processing range.

■ Optional robot, cantilever, CCD camera monitoring system for special welding.

Application:

Widely used in optical communication devices, IT, medical treatments, electronics, batteries, fiber coupled components, CRT monitor electron guns, metal parts, cell phone motors, clock precision parts, automobile lamps, etc.

Materials:

Applicable to stainless steel, carbon steel, copper, aluminum, gold,silver, chromium, nickel, titanium, tantalum and other metals or alloys.

| Product Name | Items | Spec and Brand | Mark |

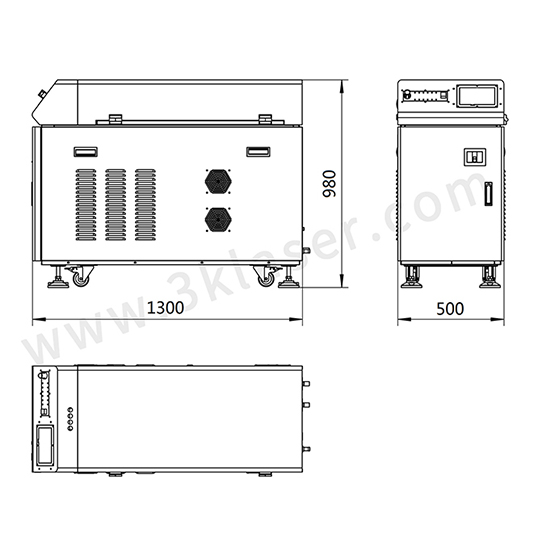

| Fiber Transmitting Laser Welding | Frame Structure | 3K Laser | as Fig |

| Laser Generator | Option | ||

| Welding Head | Option | ||

| Cooling Tank | Option |

| Performance/Model | Unit | SK-FW200 | SK-FW300 | SK-FW500 | SK-FW600 |

| MAX Laser Power | W | 200W | 300W | 500W | 600W |

| Wavelength | nm | 1064nm | |||

| Welding Depth | mm | ≤1mm | ≤2mm | ≤3mm | ≤4mm |

| Pulse Width | ms | ≤20ms | |||

| Weld Frequency | Hz | ≤50Hz | |||

| Spot Size Range | mm | 0.1-3.0mm | |||

| Spot Size | mm | 0.2-3.0mm | |||

| Machine Power | KW | ≤9KW | ≤12KW | ≤14KW | |

| Voltage | 380V/Three-phase/50Hz/40A | 380V/Three-phase /50Hz/60A | |||

| Standard workbench maximum load-bearing | Kg | ≤100Kg | |||

| Workbench Route | mm | 200* 200mm to 1200*1200mm | |||

| Workbench repeatability | mm | ±0.01mm | |||

| Positioning accuracy | mm | ±0.02mm | |||

| Aiming and positioning | Red Light、CCD Surveillance system(Rotary Optional) | ||||

| Cooling System | water cooling | ||||