- Description

- Config

- Technical

- Samples

- Video

- Download

Introduction:

Cantilever laser welding machine fuses the special welding wire to the damaged part of the mold through high thermal energy generated by laser instantaneously, and is firmly welded to the original mold base material, and is ground and polished into a smooth surface after welding, thereby realizing the repairing effect of the mold, and is effective. Repairs sand holes, cracks, chipping and worn edges, sealing edges and other tiny parts.

Feature:

■ The laser welding spot has a small diameter, a small heat receiving range, no pores after welding,

no depression, and does not cause deformation of the precision mold.

■ Deep welding depth,the welding is firm, the melting is sufficient, and there is no obvious repairing trace.

■ Use an automatic shading system to reduce the irritation of the laser.

■ The welding head can be rotated 360 degrees, the worktable can be electrically lifted, and the 3D

mobile platform is suitable for repairing different sizes of molds.

■ The parameter adjustment is controlled by an intelligent remote control, which is simple and quick to operate.

Application:

Widely used in mould making and molding industries such as mobile phones, digital products, automobile and motorcycle etc.

Materials:

Applicable to plastics mainly used in S136, SKD -11, NAK80, 8407, 718, 738, H13, P20, W302, 2344, etc., such as die steel, carbon steel, common alloy steel, stainless steel, beryllium copper, copper and hard alloy materials. Molds, casting molds, forging dies, stamping dies, die-casting dies, and the like.

| Product Name | Items | Brand | QTY | Mark |

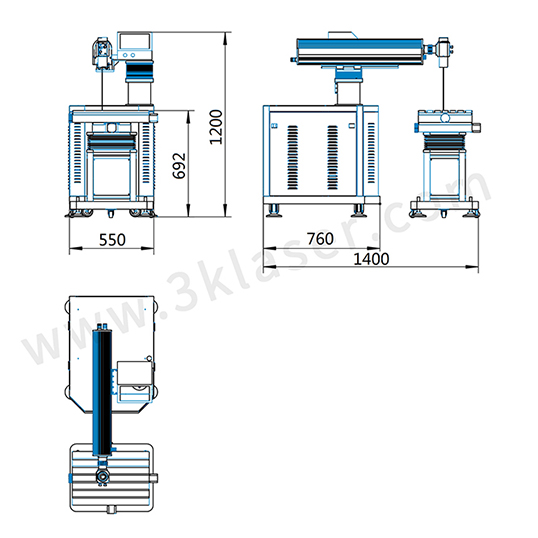

| Mold Repairing Laser Welding | Frame Structure | 3K Laser | 1SET | as Fig |

| Laser cavity | YAG | 1SET | ||

| Pulse Xenon lamp | Standard | 1Pcs | ||

| Laser Power | Option | 1SET | ||

| Fixed Laser Welding Head | Option | 1SET | ||

| Display screen | LED | 1SET |

| Performance/Model | SK-LW200 | SW-MLW300 |

| MAX Laser Power | 200W | 300W |

| Wavelength | 1064nm | |

| Max Pulse Energy | 60J | 80J |

| Welding Frequency | ≤100Hz | |

| Pulse Width | 0.1-20ms | |

| Welding Depth | 0.1-2.0mm | 0.1-3.0mm |

| Adjustable Spot Range | 0.1-2.0mm | |

| Workbench Load Bearing | ≤200kg | |

| Cantilever three-axis travel | X axis 400mm;Y axis 500mm;Z axis 1000mm | |

| Workbench three-axis travel | X axis100mm;Y axis 250mm;Z axis 400mm | |

| Power consumption | ≤8KW | ≤12KW |

| Voltage | AC220V10%/50Hz/30A C380V | |

| Control System | Microcomputer program control | |

| Cooling System | External water cooling | |