- Description

- Config

- Technical

- Samples

- Video

- Download

Introduction:

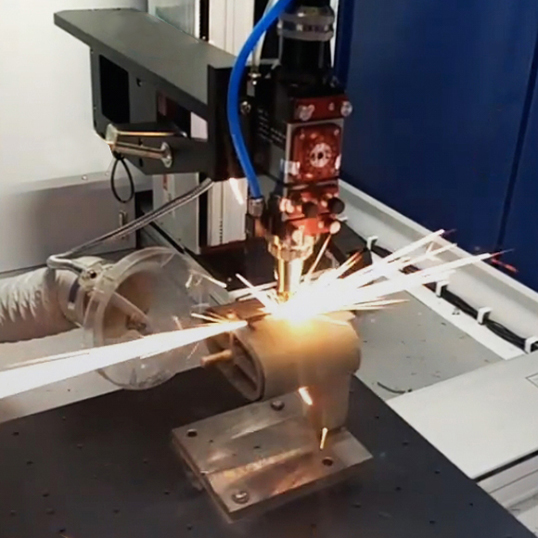

This equipment mainly performs laser cutting on products with high requirements on the quality of cutting surfaces such as super-hard material tool composite sheets, ceramics, single crystals, etc., laser focusing CCD and optical path television monitoring. It consists of a precision three-axis motion table and an industrial control computer system. The new version of the software system is developed by itself, and it can be automatically programmed with CAD graphics. The cutting surface is smooth, the clamping is convenient, and the long-term work is stable and reliable.

Feature:

■ Good beam quality, high processing efficiency, and the cutting slits are fine.

■ Good verticality, and the perpendicularity of the cutting surface is less than 1.5°.

■ The cutting slit is narrow,high yield, the edge of the cutting slit is straight, and the thermal damage is small.

Application:

Widely used in abrasives, cutting tools and other industries.

Materials:

It is suitable for high efficient cutting and precision machining of PCD drawing die, PCD laminate, CVDD, various PCBN, single crystal diamond, ceramics, silicon wafer, cemented carbide, thin steel plate and other materials.

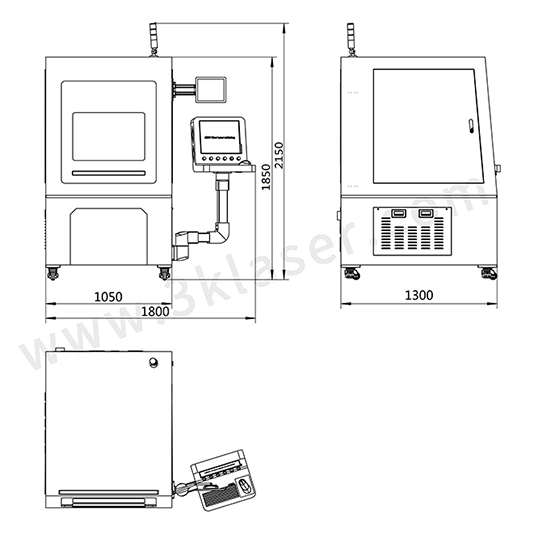

| Product Name | Items | Spec and Brand | Remark |

| Superhard Material Laser Cutting | Main Host | 3K Laser | as Fig |

| Laser Generator | Option | ||

| Special laser cutting CNC system | 3K Option | ||

| Cutting head | 3K Option | ||

| Cabinet、Operation table | 3K laser |

| Performance/Model | Unit | SK-LC300 | SK-LC450 | SK-LC600 |

| Wavelength | nm | 1064 | ||

| Repeatability Frenquency | Hz | 1-300 | ||

| Min Spot Size | mm | <0.05 | ||

| Max Cutting Thickness | mm | ≤8 | ||

| Max slit width | mm | ≤0.1 | ||

| Max line cutting speed | mm/s | 10 | ||

| PCD Processing speed | mm/s | 0.5mm/s(δ=2mm) | ||